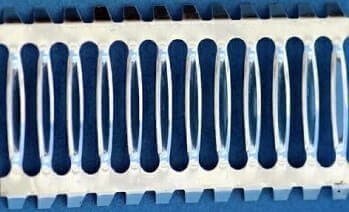

In the torsion spring multilams, the contact force is applied by torsion of the contact blades webs.

This design has the advantage over the claimed on bending leaf spring multilams webs that the spring characteristic and thus has an enlarged working area.

The main advantage, however, is the direct current path between pin and socket.

The electrical current to be transmitted is directed by the shortest route from the pin into the socket.

For attachment in the socket or the plug body, the torsion bar bands have a lateral toothing with selectable bending angles.

Analogous to the leaf spring contacts the torsion spring contacts are simply fixed in a groove of the contact part.

Usually torsion spring multilams are designed as socket contacts. This simplifies the assembly and has the advantage,

that the lamellar contact is protected against external mechanical influences in the socket.

Diameters starting from 20 mm should be designed as socket contacts, since the contact lamella as a plug contact without special fixation does not have sufficient hold on the plug pin.

The 13 mm wide band has a grid of 2mm, the 17.5mm wide band of 2.5mm.

The contacts can be supplied as cut-to-length flat or pre-rounded contacts.

The ACA torsion spring multilams are made of copper beryllium. The surface is usually silvered and passivated.

The ACA torsion spring multilams are compatible / interchangeable with multilams of common manufacturers.

Application of the ACA torsion spring multilams for transmission of very high power to a flange.